Roofing & Wall Panel

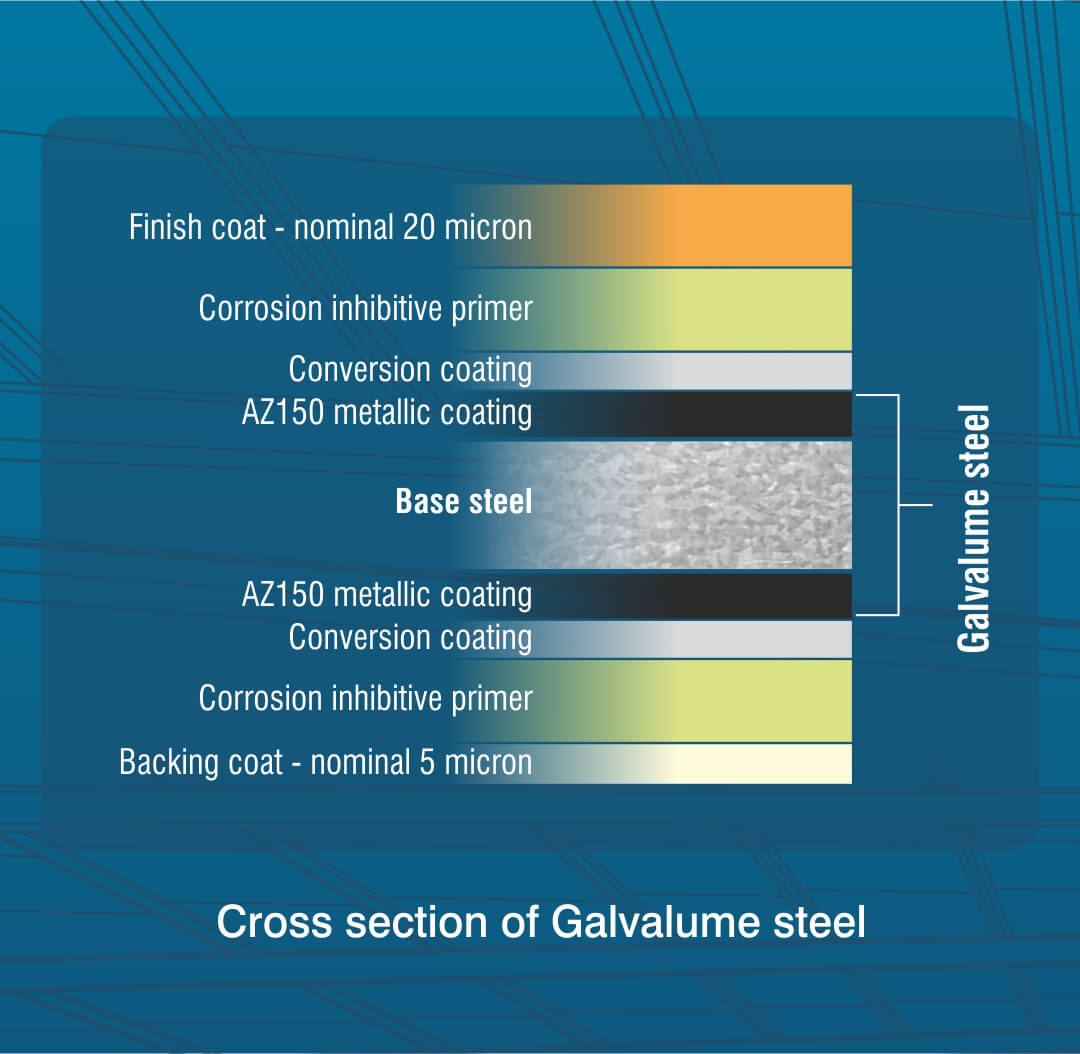

The Base Steel

Superior Corrosion Protection

Durability

Galvalume is a better substrate for the application of finishes than a galvanized finish. Galvalume coated panels have a super smooth surface that readily accepts almost any finish for a longer more durable life. Due to the unique spangled structure of galvalume steel, the product retains its luster for a longer time, coupled with the traditional resistance to corrosion provided by the alloy-coating to keep it looking good over a longer period of time. Single length, continuous sheets (as per shed size) reduces over laps and makes it watertight. Without sacrificing coating adhesion, galvalume steel sheet can be bent or roll formed. Its oven-baked finish ensures it stands the test of time and resists chipping, cracking and peeling. It is non-combustible and termite resistant.

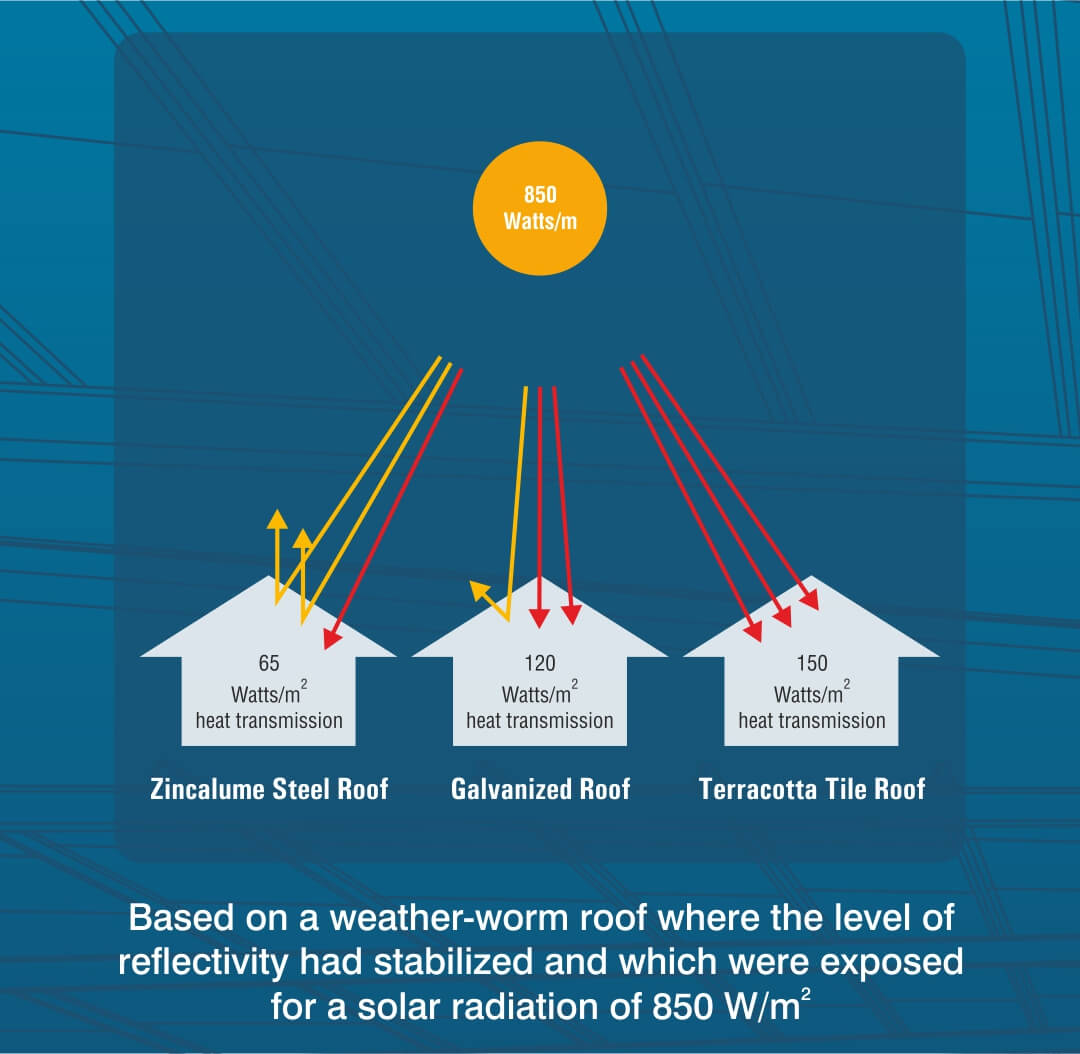

Thermal Resistance

Its attractive shiny appearance reflects a very high percentage of heat and light and can withstand 0 operating conditions of up to 315 c/600f without surface discoloration. Since it reflects a high percentage of heat and light, the heat radiated inside the shed is minimal in comparison to other roofing material. Steelfab® sheeting offers high thermal performance, dissipating heat rapidly in warm climate and saving power considerably. Its weather-resistance capacity is far superior to alternative steel roofing material. Steelfab® sheeting employs the use of light colour back coats to reflect internal light, thus cutting down on illumination costs.

Based on a weather-worm roof where the level of reflectivity had stabilized and which were exposed 2 for a solar radiation of 850 W/m2

Superior Paint Technology

The combination of resins and inorganic pigments used in steel, provides it with the ability to resist colour changes longer than most colour-coated alternatives in extreme environments. G steel

paint systems are designed for exterior environment and conform to latest International standards.

On an average Galvalume Steel AZ150 (Al + Zn Coating of 150gsm) lasts up to four times more than Galvanized steel (Z275 i.e. Galvanized coating of 275gsm)

Tested Tough

Exposure tests in the US over the past 14 years have proven the superior toughness of . The conditions and results of these tests are shown above. Rainwater sample tests have also proved zinc-aluminium alloy coatings to be superior. These tests used both distilled water and impure water containing chloride. The distilled water tests showed that galvanized corroded almost 60 times faster than coatings. The corrosion rate of galvanized in the impure water test was 10 times faster than the coated steel.

Low Maintenance

Steelfab® steel sheets require virtually no maintenance. Normally damage to roofing is caused by pounding of water, accumulated leaves and other debris. By carrying out annual inspection and cleaning, roofs can stay in excellent condition.

Cost Effective

Due to High-Tensile properties of Steelfab 1000™ steel sheets and low weight per square meter as compared to the conventional roofing material, the sheets are very strong and durable. So one can reduce the number of purlins by increasing the purlin spacing, saving considerably in the overall weight of the shed and reducing the overall cost of the shed and civil foundation. Overall cost of the sheet is again reduced by its long life cycle and virtually no maintenance cost.

Environment Friendly

Steel is one of the world's most recycled products. In fact, over one million tonnes of steel are recycled every day worldwide. Steelfab 1000™ roofing sheets and cladding sheets can also be similarly recycled.

Aesthetics

The resin coating on galvalume steel provides excellent mark resistance qualities, translating into a better- looking product for the customer. It has a handsome silvery matte finish and does not have the harsh glare of traditional chromated galvanized sheets. The variety of colours and shapes possible with galvalume steel is limited only by your imagination. Galvalume steel is largely used in the construction industry where long life is critical; it can be seen in projects worldwide where it has been successfully used for roof and wall cladding. Its ability to weather evenly over a period of time so as to provide a consistent colour across the exposed surface makes it a unique product.

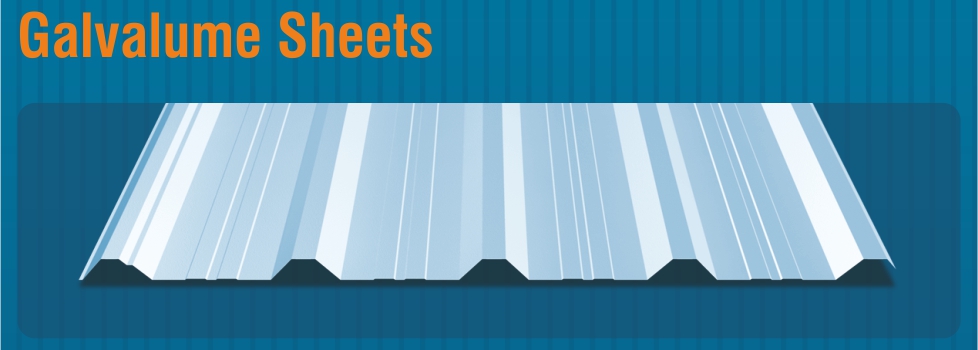

Galvalume Sheets

The revolutionary 55% Aluminium + 43.5% Zinc + 1.5% Silicon alloy coated steel sheets,imparts exceptional corrosion protection properties & excellent aesthetic,a world patented coating and process of BIEC International, USA who owns the trademark “ Galvalume” Material sourced from world's best manufacturers of colour-coated Galvalume Steel and profiled on most advance state-of-the-art machines based on latest US technology.- Used for roof cladding & side cladding.

- Steelfab uses Al-Zn alloy coated steel sheets which are available in both High tensile( 550 Mpa ) & in soft steel ( 300 Mpa).

- Color coated sheets are as per AS 1397.

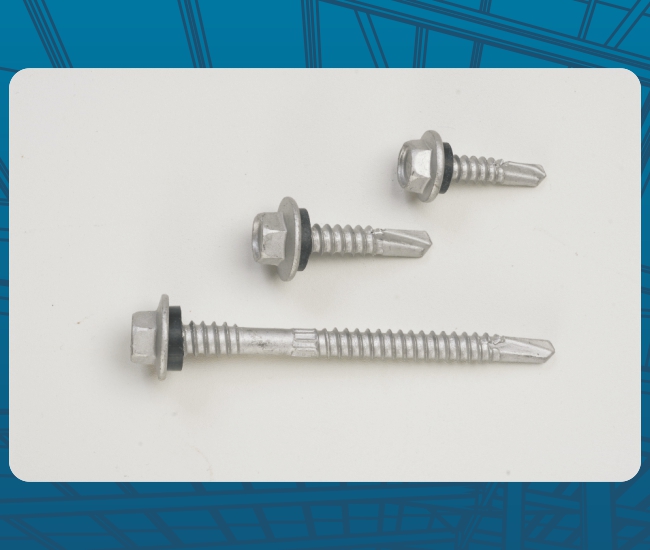

Fasteners used

Xylene coated Self Drilling Screw

Advantage

- High tensile steel base

- Superior corrosion protection

- Durability

- Thermal resistance

- Low maintenance

- Cost effective

- Environment friendly

- Aesthetics

- Available in various profiles & colors

Pre Painted G.I. Sheets (PPGI)

The traditional hot dipped Zinc coated steel sheets,imparts normal corrosion protection properties which is universally known as 'Galvanized'.Technical Specification

- Used for roof cladding & side cladding

- Steelfab uses Zn coated steel sheets which are available in both High tensile ( 345 Mpa ) & in soft steel ( 240 Mpa)

- Color coated sheets are as per IS 227

Fasteners used

Hot dipped Zinc coated self drilling screw.

Advantage

- Low tensile steel base

- Traditional corrosion protection

- Optimum durability

- Low thermal resistance

- Low maintenance

- Cost effective

- Environment friendly

- Available in various profiles & colors

Material Specification

|

Products |

Base Steel |

Base Steel |

Base Metal Coating |

Colour Coating |

|

Colour-Coated AI-Zn alloy |

G 550 |

0.50 mm TCT |

Zinc-Aluminium |

Regular Modified Polyester (RMP) |

|

Bare AI-Zn alloy coated Steel |

0.50 mm TCT |

Bare AI-Zn |

||

|

Pre-painted Galvanized Steel |

240 Mpa |

0.60 mm TCT |

Galvanized IS-277 |

Regular Modified Polyester (RMP) |

|

Galvanized Steel |

-- |

24G (0.6 mm), 26G (0.5 mm) |

Galvanized IS-277 |

-- |

Comparison Between Galvalume & Galvanized Sheets

|

Sr No |

Propertise |

Galvalume |

Galvanized |

|

1 |

Tensile Strength |

550 Mpa |

240 Mpa |

|

2 |

Coating |

Al + Zn + Si |

Zn |

|

3 |

Coating Thickness |

AZ 150 gsm |

Z 120 gsm* |

|

4 |

Heat Transmission |

65 watt/m2 |

120 watt/m2 |

|

5 |

Mark Resistance |

Excellent |

Normal |

|

6 |

Corrosion Protection Properties |

Very high |

Standard |

|

7 |

Environmental Resistance |

Suitable for extreme |

Suitable for moderate |

|

8 |

Color Weathering |

Uniform color weathering |

Abnormal color weathering |

1. SteelFab Seam Roof

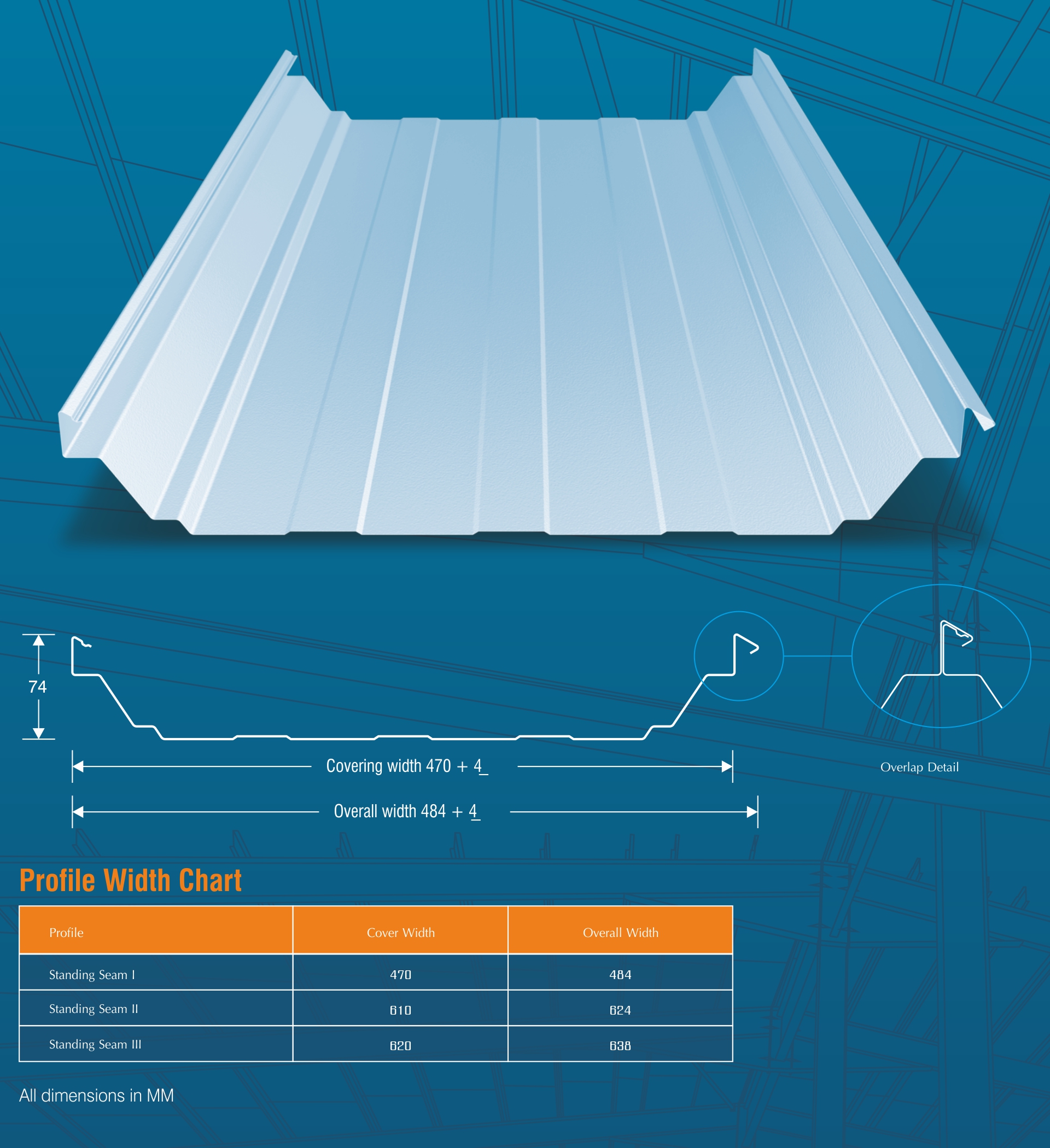

Standing Seam Roof System

The standing seam metal roof system is one of the most exciting breakthroughs in roofing technology in 25 years. It fulfills the building owner's need for durable, puncture-resistant protection against the weather, while working along with the forces of nature. In US, the system currently accounts for well over one billion square feet of roofing, with potential to capture a much larger share of the commercial and residential building market. Unlike flat built-up roofs, which require frequent maintenance, the standing seam metal roof offers 20 years and beyond of trouble-free performance with little or no maintenance time or expense.

Advantages of Standing Seam Roof System

Long Lasting

Standing seam metal roof systems are well known for their long life span. The use of strong durable materials coupled with the superior leak free technology makes Standing seam a wise investment. Standing seam pays for itself over time by reducing or eliminating the cost of roof maintenance and replacement while lowering energy costs. Standing seam also relieves the frustration of dealing with the constant failures of flat roof systems.

Sturdy and Durable

Standing seam metal roofing is designed to withstand the elements. High quality finishes, special connections and heavy 24 or 26 gauge steel construction give Standing seam the ability to out-perform all other roof systems in resisting damage from hail, rain, wind, solar rays, thermal movement and foot traffic. Durability is part of the reason standing seam performs so well over long periods of time and makes standing seam an obvious choice for owners who need a new roof with a long life span.

Virtually Leak Proof

Panels are joined together by overlapping seams that are elevated above the roof plane, hence the name "Standing Seam". Hidden inside the seams are panel clips that hold the panel to its supporting structure. These panel clips eliminate the need for exposed screws to hold the roof in place. The panel seams are filled with factory applied sealant and mechanically crimped together forming a weather tight seal against the elements. A leak free roof reduces worries about water damage, mold, musty carpet, rotted roof and wall structures, roof repairs and roof replacement.

Low Maintenance

Standing seam roofing needs almost no maintenance needed other than a periodic cleaning of the guttering. The low maintenance of standing seam saves your time, frustration and money.

Optional Low or Steep Sloped Roof

Standing seam metal roofing is very versatile. It can be installed over low sloped structures for a high quality low cost roof or it can be installed in steep sloped applications for a more aesthetic appearance.

Easy to Insulate and Highly Energy Efficient

Standing seam metal roofing can obviously be installed with as much insulation as needed to meet the owner's insulating requirements. Standing seam also keeps the insulation dry so that it can effectively do its job. Obtaining and keeping high R-value, costs less in the installation phase as well as in monthly energy bills.

Good for the Environment

By stopping leaks inherent in flat roofs: Standing seam creates an environment less conducive and leaks from flat roofs allow moisture in walls and floors. The building's occupants enjoy a healthier environment.

All in All

- SSR is the most Advanced and Exciting Breakthrough in roofing technology in last 25 years

- Long lasting

- Sturdy and durable

- Virtually leak proof roof

- Low maintenance

- Can be used in low or steep sloped roofs

- Easy to insulate and highly energy efficient

- Good for the environment

- A unique clip design

- Perfect for high wind areas

- High end look

- Incredible versatility

- Manufactured on State-of-the-Art machines employing the latest technology from USA

Uniqueness of Steelfab Seam Roof

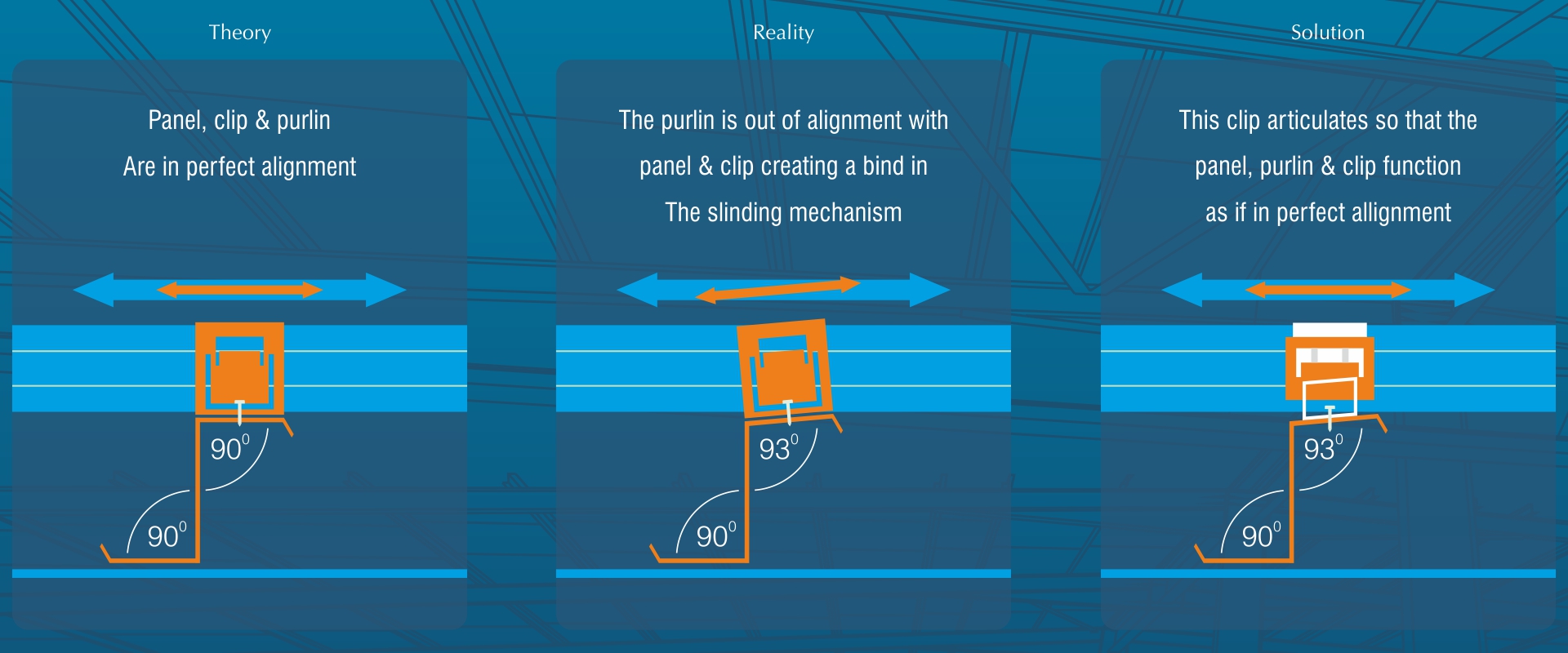

Fixing Arrangement: The Unique Clip Design

Articulating Clip Eliminates Binding and Friction

There are many styles of standing seam clip systems available. However, Steelfab® offers the only clip that articulates, with floats which eliminates binding and friction.

Eliminates Binding

This clip articulates between the base and intermediate section without binding. Typically, binding on the clip is attributed to misaligned or out-of-square purlins. The bind restricts a standing seam roof from properly floating the way it was designed.

Eliminates Friction

The floating section of most clip systems grabs only the top portion of the male leg of the panel while the fixed section of the clip supports the bottom male leg. When expansion and contraction occur, the top portion actually moves with the panel as the bottom portion remains fixed. This creates friction or drag between the clip and panel greatly restricting movement. The articulating clip, which allows for 2 ½" of slide per clip, supports both the top and bottom of the male leg eliminating the friction and allowing the panel to float freely as it was designed.

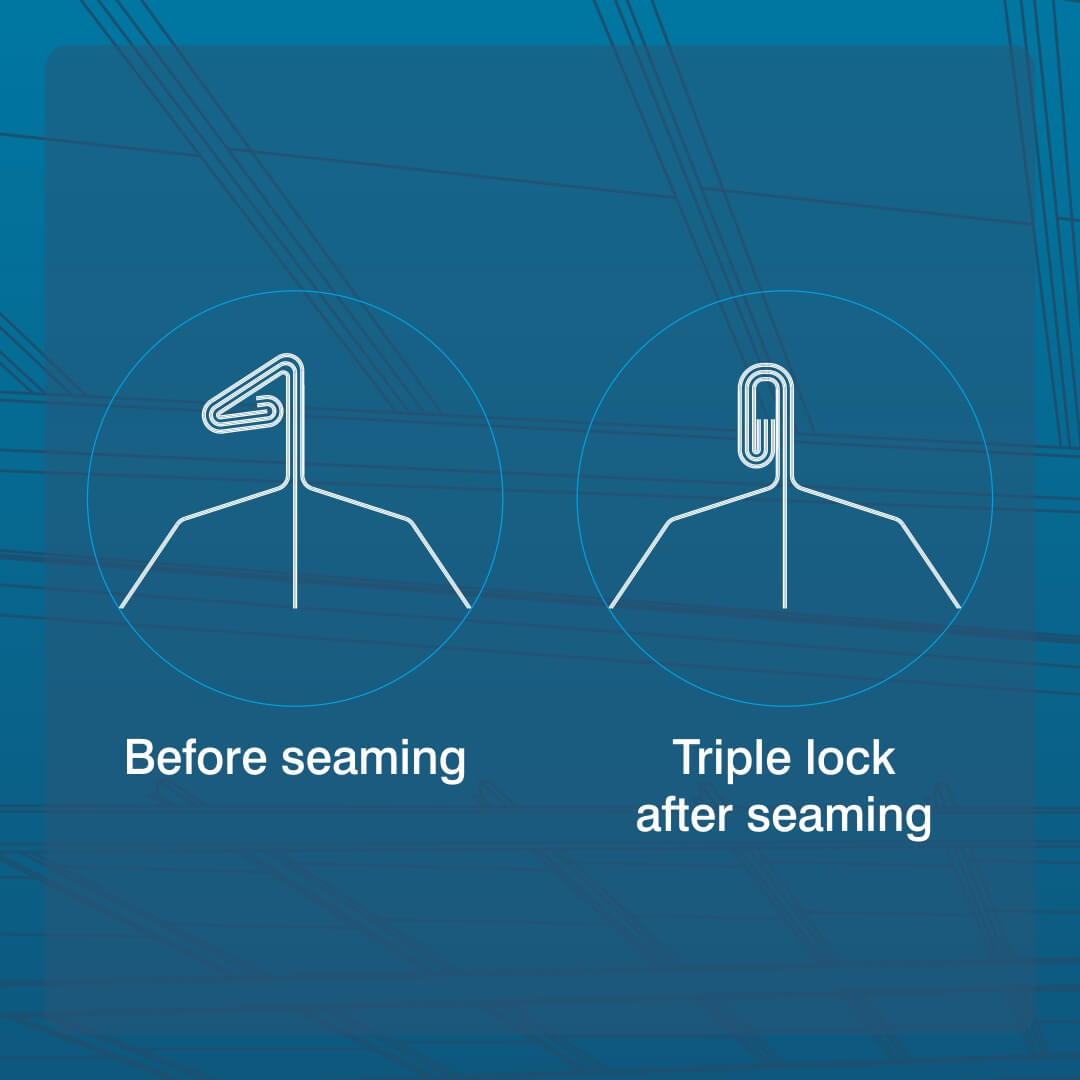

The Revolutionary Seam

The term standing seam is used to describe any type of joinery that uses an upturned portion of the metal to connect adjacent metal sections. The joinery raises the seam above the drainage plane of the panel creating its distinctive vertical lines. There are various joinery system available in the industry but Steelfab seam roof system has unique Triple-Lock joinery system which is much advanced and the stronger than other systems.

The superiority of Triple-Lock joinery system over other joinery system can be understood from following description:

Triple Lock Seam

The Triple Lock seam is accomplished by seaming with an hand seamer first & then with electrical

seamer. It's the only seam in the market to use the 360 degree + 90 degree seam which:

•Structurally isolates the seam from the effects of severe wind lodging by placing load resisting bends between the seam and clip hook and the stresses of panel deflection.

•Isolates the seam sealant from dislodgment or separation during sever wind lodging, thereby assuring a water resistant seam throughout the life of the roof.

•100% better than snap on panels, as there is no chance of seam opening up as in the case on snap on, where the sheets are likely to get flown off during heavy winds.

Fool-proof installation all that is required is the placement of the electrical seaming machine on theseam to begin the seaming process. Its virtually impossible for the seamer to run off the seam until it comes to the end of the panel or is removed by the operator.

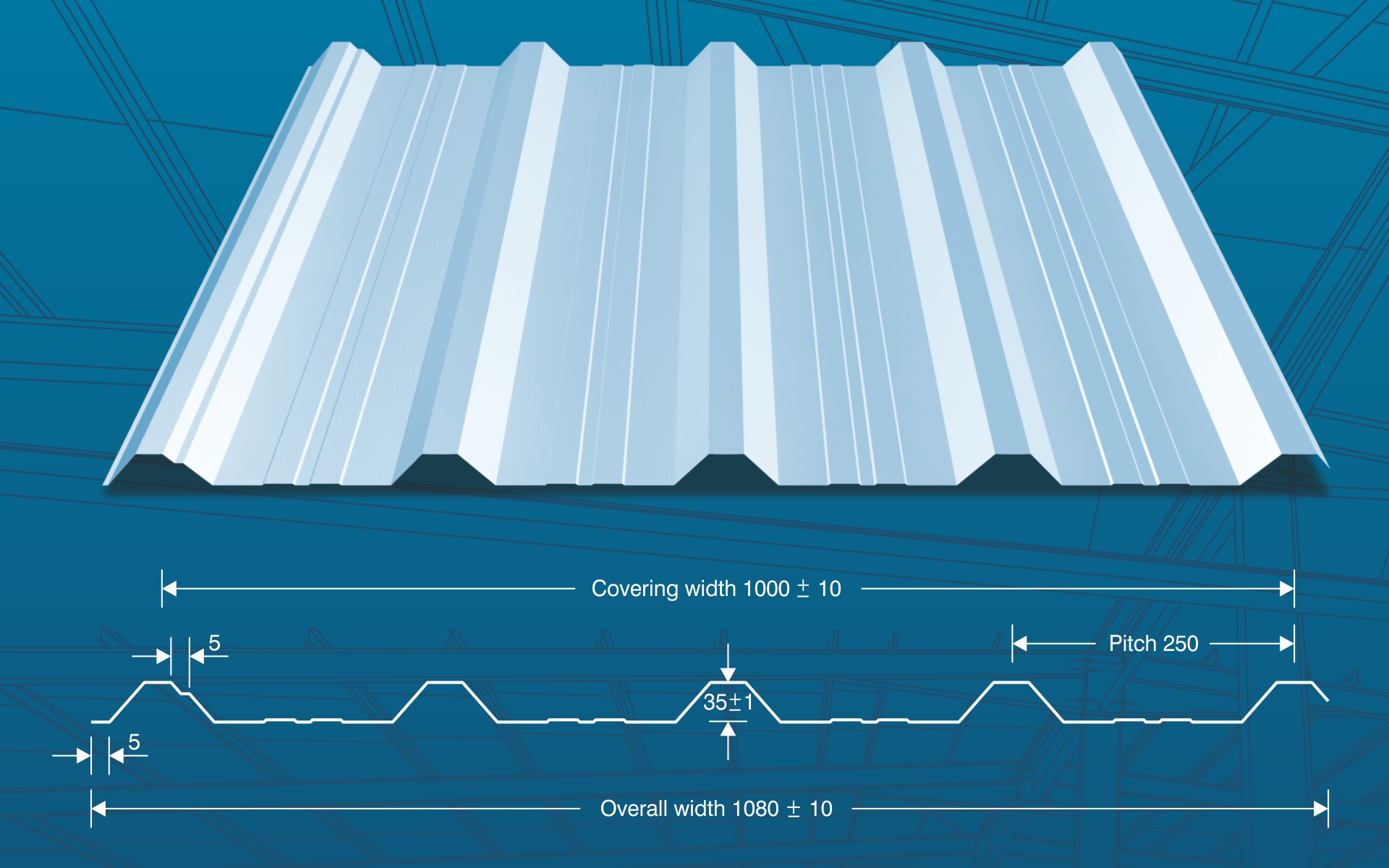

2. Steelfab 1000(TM)

The Universal Trapezoidal Sheets

The most universal and standard panel for roofing & cladding application,

Steelfab 1000TM has been defined to withstand the extremities in climatic conditions in India the heaviest of rainfalls, hottest of summers and the most dynamic of temperature fluctuations.

Features

- Strongest panel with highest rib height of 35 mm and pitch of 250mm with two mini ribs

- Specially designed anti-capillary groove of 5 mm to prevent any possible leakage, as in the illustration

- End leg of 5mm to give stability and support, as in the illustration

- Best covered width ratio

- Most advanced panel available for roofing and cladding in the industry

- Manufactured on state-of-the-art machines employing the latest technology from USA

Available Finish

- Colour coated Al-Zn coated steel

- Bare Al-Zn coated steel

- Pre painted galvanized steel (PPGI)

- Galvanized steel

Available Length

- Standard length 2m, 2.5m, 3m

- Any transportable length ie from 1m to 14m and beyond according to the requirement of the customer on request

Application

- Roof cladding

- Wall cladding

Available Thickness

- Colour coated Al-Zn alloy coated steel (550 Mpa / 300 Mpa) 0.50mm TCT

- Bare Al-Zn alloy coated steel (550 Mpa / 300 Mpa) 0.47 & 0.5mm TCT

- Pre-painted Galvanized steel (PPGI) (240 Mpa) 0.50mm & 0.60mm TCT

- Galvanized steel (PPGI) (240 Mpa) 0.50mm & 0.60mm TCT

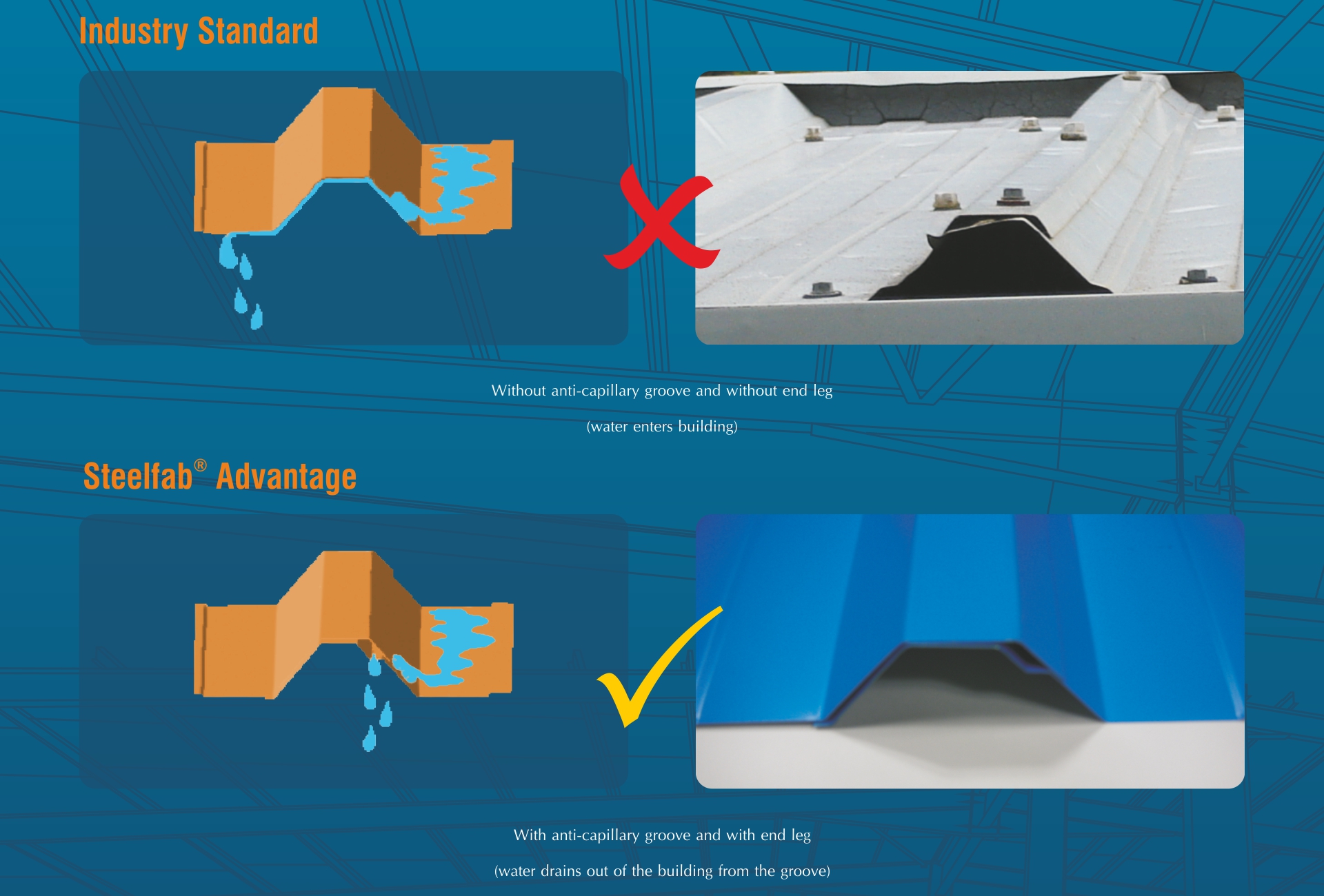

Uniqueness of Steelfab 1000TM

Specially Designed Anti-capillary Groove

A specially designed anti-capillary groove of 5 mm is provided in the sheet profile to prevent any possible leakages in the shed. Normally, during heavy rains, there is a tendency of water to rise between the overlap of the sheet due to capillary mechanism, hence crossing the crest of the sheet and entering the shed. To restrict this capillary tendency of water, we have designed an anti capillary groove, which restricts water from rising beyond the groove and provides a complete leak-proof solution to the shed.

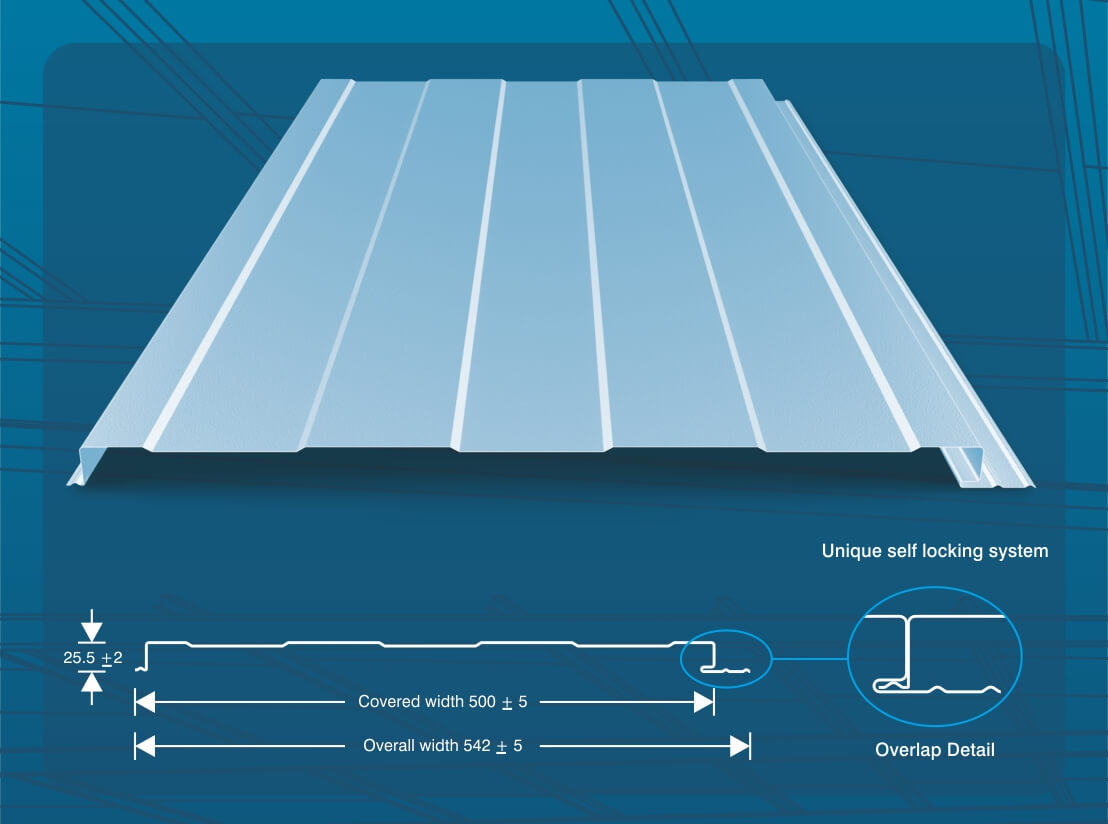

3. Steelfab Architectural Wall 500

Bolt Hidden Wall Pannel

Steelfab Architectural Wall 500 gives a smooth, clean look for any building. Since outside surface of the building is smooth, it provides the rich appearances. Each panel is fastened to the wall structural system and then locked in to the adjacent panel, concealing the fasteners. The hidden fastener not only provides an enhancement to the building appearance but also improves its security.

Features

- Aesthetically beautiful

- Hidden bolt system

- Perfect combination of strength and aesthetic

- Unique self locking system

- Best covered width ratio

- Latest innovation in the roofing industry

- Engineered to last a lifetime

- Insulation material can be used to insulate the building

- Designed using the latest US technology

- Manufactured on state-of-the-art machines employing the latest technology from USA

Available finish

- Colour coated Al-Zn coated steel

- Bare Al-Zn coated steel

- Pre painted galvanized steel (PPGI)

- Galvanized steel

Available length

- Standard length 2m, 2.5m, 3m

- Any transportable length i.e. from 1m to 14m and beyond according to the requirement of the customer on request

Available thickness

- Colour coated Al-Zn alloy coated steel (550 Mpa / 300 Mpa) 0.50mm TCT

- Bare Al-Zn alloy coated steel (550 Mpa / 300 Mpa) 0.47 & 0.5mm TCT

- Pre-painted galvanized steel (PPGI) (240 Mpa) 0.50mm & 0.60mm TCT

- Galvanized steel (PPGI) (240 Mpa) 0.50mm & 0.60mm TCT

Application

Wall Cladding

Sheeting Accessories